MovingLight®, part 3 of 3 | October 4, 2016 | By Alan Benlolo

Curing Efficiency – Experiment# 1

For this and the following experiments, we’ll hold the XYZ resolution, layer thickness, light source/intensity, and resin constant. Note that I have used the terms “conventional DLP process” and “DLP printers” interchangeably.

Conventional DLP Process

(single-projection curing)

Figure A. The projected illumination or “projected area” remains constant for all layers of the build. In this scenario, we assume that the projected area is equal to the area of the platform. The “dead zone” refers to the UV-exposed areas not cured by the light.

MovingLight® technology

(positional curing)

Figure B. The projected area (also referred to as the “tile size”) measures 70 x 40 mm and remains constant for all builds. This layer will undergo multiple projections as opposed to a single one.

Curing Efficiency – Experiment# 2

Conventional DLP Process

(single-projection curing)

Figure C. The single projection yields a low efficiency rating. Unlike MovingLight® (see right), the printer does not automatically position the UV illumination based on the layer’s location on the platform. Regardless of the layer’s size and position, it is exposed to the same amount of light as all the other layers in the build.

MovingLight® technology

(positional curing)

Figure D. MovingLight® is “smart” in that it cures where it needs to cure. The moving DLP projector directs light based on the location of the curable image patterns of the layer, minimizing wasted light and maximizing build speed.

Curing Efficiency – Experiment# 3

Conventional DLP Process

(single-projection curing)

*Figure E. Despite reducing the projected area by half, the curing of the layer is still less efficient than MovingLight® (see right).

MovingLight® technology

(positional curing)

*Figure F. Six projections to yeild a relatively high curing efficiency rating.

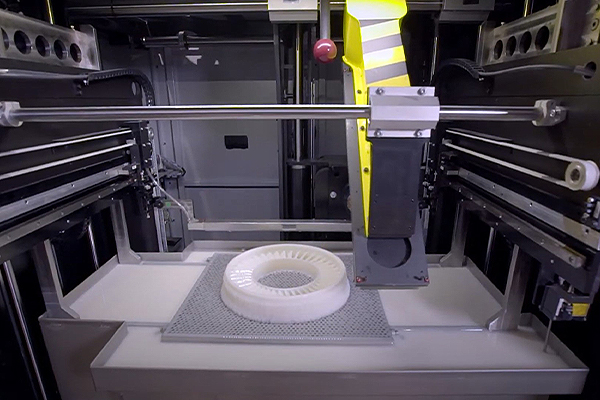

MovingLight® in Action!

*Figure G. The projector, powered by a 1080p DLP chip, moves vertically and laterally to cure tile slices of the layer. Each projection delivers the same resolution at any point on the platform.

Conclusion

Because MovingLight® directs UV light based on the curable image areas of the layer, it is vastly more efficient than conventional DLP 3D printers that employ a fixed projector, whose position along with the projected area (the light exposing the layers) are pre-set before each build cycle. This increase in curing efficiency lends to faster build times.

Our experts

are here to help

Get a quote

6956 Jarry Est, Saint-Leonard, H1P 3C1, (QC), Canada

438.738.4133

855.738.4133

sales@genistar.com